The UNH John Olson Advanced Manufacturing Center serves as a resource for industry; providing information, education, collaborations, and solutions related to advanced manufacturing, materials, and product innovations. Interconnecting manufacturers and the University, the Olson Center provides industry with access to the expertise and resources of the University and students and faculty with access to industrial environments and applications.

Collaboration Models

Faculty & Staff Led Projects

These projects are fully conducted by university R&D faculty, staff, and interns. This option involves co-development by the university and industry personnel. Projects frequently have weekly or bi-weekly meetings with industry and industrial researcher space may be allocated at the Olson Center.

Student Integrated Projects

These projects are integrated with university R&D faculty, staff, and students as a part of the University’s core learning environment. These projects usually involve larger scopes of investigation or development with a longer project duration.

Student Led Projects

These projects are completed by university students in a learning structure. Projects conducted using this option tend to require the least industrial resource allocation with respect to budget and internal personnel time.

To read about recent collaborations, visit our News and Events tab

Light Sensors for Forest Canopies & UNH Earth Systems Research Center

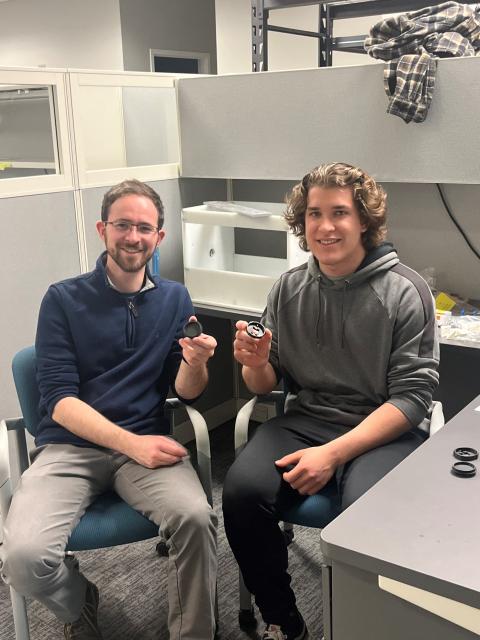

Over the summer of 2022, the Olson Center worked on a project for the Terrestrial Ecosystems Analysis Lab which is a part of the Earth Systems Research Center at UNH. Jack Hastings, along with the PI of the lab, Dr. Scott Ollinger, have been working to prototype low-cost light sensors to deploy in forest canopies. They are interested in understanding how light is intercepted and moves through different tree species.

The sensor will measure what specific wavelengths of light are reaching the sensor at different times of the day. Mechanical engineering intern, Seth Chartier, stepped in to build a prototype of the low-cost weatherproof sensor housing using our 3D printer. Eventually, Hastings wants to deploy many sensors in the forest to learn more about the quantity and quality of light received by trees.

Written by, Jesse Davis

GreenSource Fabrication

The University of New Hampshire (UNH) has been steadfastly committed to sustainability, a principle deeply ingrained in its academic and research endeavors. One striking example of this dedication is the collaboration between UNH's Olson Center and GreenSource Fabrication (GSF), a pioneer in sustainable printed circuit board (PCB) manufacturing. With 50% of its engineering staff consisting of UNH alums, GreenSource Fabrication forms a robust collaborative front firmly grounded in shared values of sustainability.

Operating under their parent company and Olson Center supporter Whelen Engineering, GreenSource Fabrication is a company that exemplifies the fusion of technological innovation and environmental consciousness. GSF has created a waste treatment system—a closed-loop marvel that purifies and recycles the same volume of water 10 to 12 times a day. Remarkably, GSF consumes less than 400 gallons of water daily for its operations. A typical operation of their size would consume over 50 times that amount.

Since 2022, GreenSource employee and UNH alumna Maria Virga has run an internship program for UNH students at the Olson Center. The internship allows students to gain practical insights into cutting-edge technology for printed circuit boards. More significantly, it exposes them to revolutionary sustainable production methods beyond the typical classroom curriculum. Through hands-on experiences with GSF's state-of-the-art equipment, students learn the technical aspects of circuit board fabrication and the critical importance of environmental consciousness in manufacturing.

Interns at the Olson Center can engage with GSF's cutting-edge equipment, including the InduBond X-Press. This machine plays a crucial role in GreenSource's lamination department by utilizing heat and pressure through induction to efficiently laminate circuit boards, thereby reducing cycle time. Interns gain valuable hands-on experience as they interact with this impressive equipment. The InduBond X-Press serves as a prime example of GSF's dedication to offering interns a valuable and enriching learning experience.

GSF showcases that environmental responsibility can go hand in hand with cutting-edge technology. The Olson Center is proud to collaborate and share space with GreenSource Fabrication as they engage students to push the sustainability envelope.

Written By, Katelyn Clark ‘24

LanAir Commercial Aviation

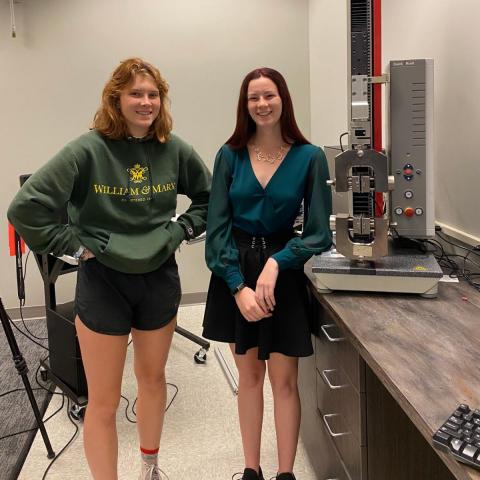

The Olson Center recently collaborated with LanAir, an incorporation that provides quality, cost efficient solutions to Aerospace customers worldwide. Olson Center interns, Delaney Cox and Josie Crotty spent about three weeks using the center’s compression machine to compare the sheer strength of a pin LanAir created to a sheer pin from an aircraft.

LanAir visited the Olson Center to view the sheer pin testing and discuss the data our interns, Delaney and Josie gathered. This is just one of the many exciting collaborations the Olson Center has had the opportunity to be apart of.

Written by, Jesse Davis