The Olson Center has an array of capabilities to aid most manufacturing needs. From Software and Sensor Development to Reverse Engineering, the center is on the brink of groundbreaking manufacturing technology.

-

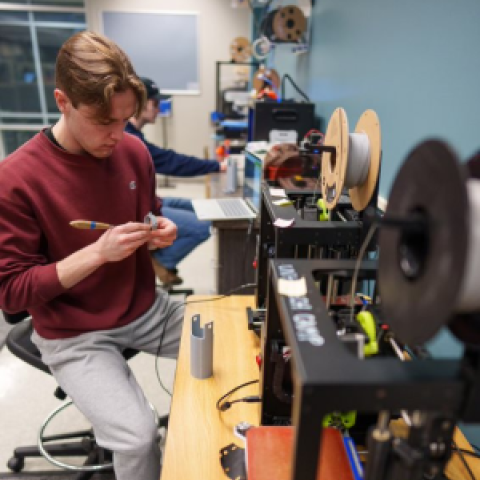

3D Printing

3D PrintingThe center has access to over sixty 3D printers, both traditional and biological. The smallest of these being the nano scribe printer, which can print nano-sized parts. At the opposite end of the spectrum, is a printer that can print 65ft by 10ft by 10ft.

Additional printing capabilities include a wide range of materials, such as a variety of plastics, metals, and concrete. The unique acquisition of biological printers allows for producing cellular cultures.

Photo by UNH Photographer Jeremy Gasowski

-

Rapid Prototyping for Sheet Metals

Rapid Prototyping for Sheet MetalsWith the ability to rapidly create sheet metal parts through dye less forming technique, the center can eliminate the time-consuming nature of dye forming technology. The process includes direct CAD to part software which can create parts as small as a fraction of an inch to parts as large as 100 ft by 25 ft. This process uses touchless forming through electromagnetic technologies which pair well with biomedical applications.

Pictured are interns at the Incremental Forming Machine

Photo by UNH photographer Jeremy Gasowski

-

Automation

AutomationUsing robots produced by major manufacturers featuring electronic eyes, light curtains, and other digital factory automation, the center can assist in projects such as robotic programming and system integration. These automations allow to form complex surfaces, teach robot programming and integration, as well as perform 3D plasma cutting and much more.

Photo by UNH photographer Jeremy Gasowski

-

Material Characterization

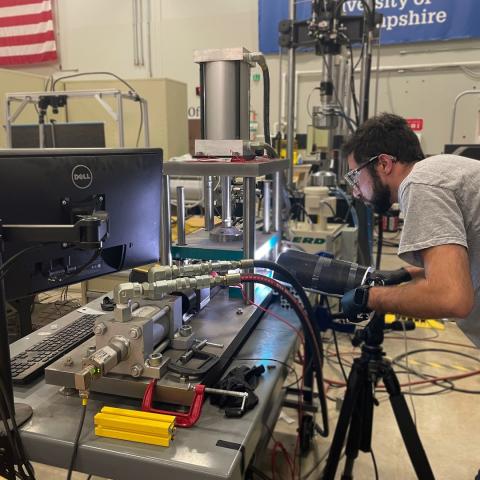

Material CharacterizationThrough its own equipment and in partnership with the University Instrumentation Center, The Olson Center can perform a multitude of characterization tests. Mechanical Testing and Multi- Axial loading are two key parts of characterization testing. The centers can perform creep, fatigue, elevated and sub-temp testing. In addition, they can perform biaxial and bidirectional compression testing, and have SEM, X-Ray de-fraction, EBSD, DMA and DSC testing equipment.

Photo by UNH photographer Jeremy Gasowski

-

Software & Development

Software & DevelopmentThe Olson Center is dedicated to working on the development of new applications, such as, Tool breakage, Condition Monitoring, Programming of Virtual Reality, Augmented Reality, Cyber Security, Modeling Simulation Software and Digital Twins Simulation.

Photo by UNH photographer Jeremy Gasowski

-

Design & Reverse Engineering

Design & Reverse EngineeringCreating new product designs by unraveling old product systems is one capability that sets the Olson Center apart from other manufacturers. Through the reverse engineering of legacy parts, the center can build upon past knowledge to better repair and understand the systems of today, which proves useful in the sustainability of modern manufacturing.

Photo by UNH photographer Jeremy Gasowski

-

CNC Machining

CNC MachiningThe center offers a diverse range of machinery for cutting different metals. The machine range includes Water Jets, Plasma Cutters, and CNC Mills, each of which can be customized to meet specific needs. The center equipment is designed to facilitate the manufacturing of not only simple flat parts but also more complex five-axis machine parts.

Pictured are interns working at the abrasive water jet cutter

Photo by UNH student Charles Jones, Class of 2026