With the democratization and commercialization of space poised to springboard the next generation of space technologies, scientific discoveries, and explorations, distinct advantages will be realized by whichever nation first establishes these “factories-in-space” for manufacturing, assembly, repair, and reclamation in non-terrestrial environments. Recent advancements in the space industry have brought humanity closer than ever to exploring potential ways to utilize space resources and protect the Earth’s environment. With the emerging interests and technological advancements in in-space manufacturing (ISM), it is of utmost importance to conceptualize the fundamental principles of ISM sustainability and to guide its technological development through these principles to ensure that the pursuit of progress aligns with the goals of environmental stewardship and long-term viability. There is a significant national need to advance sustainable ISM to be a world leader in such knowledge and technologies, as is reflected in the current Administration’s budget priorities and critical emerging technologies list. The long-term Earth and humanity benefits from ISM are beyond imagination, especially in face of the multitude of global pressing challenges related to climate change, resource depletion, environmental pollution, and population growth. As such, the overarching goal of this project is to enable a sustainable space industry that minimizes or reduces its impact on the Earth and space environments. This project intentionally integrates research with extensive education and workforce development opportunities to provide career awareness and preparation in support of a future diverse and inclusive workforce, who are knowledgeable in technical and societal best practices for ISM.

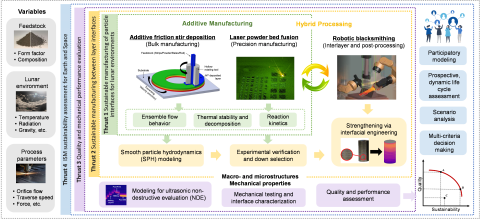

This project seeks to understand the physics that underlies the sustainability and quality of ISM to confront the pressing global challenges associated with climate change and societal development. The proposed work converges multi-process and multi-material interfacial manufacturing, sustainable engineering, and participatory science to serve as a benchmark to re-imagine a new form of space commerce that manufactures at the point-of-need. Particularly, we will investigate how existing resources in space, such as space debris (i.e., AA2219) and lunar regolith, can be used to manufacture products for use in space and to reduce the materials supplied from Earth. We will identify the mechanisms by which the variables akin to multi-material and multi-process interfacial engineering influence the sustainability and quality of ISM products. The vision is to realize a flexible hybrid ISM platform allowing the fabrication of an array of specialty, one-off parts using resources available in space with the Earth and space environmental impacts and benefits clearly and accurately assessed and attained. The overarching hypothesis for the project is that the increased lunar regolith composition and improved hybridization process design will lead to co-improved ISM quality and sustainability. This research integrates approaches and tools, including participatory modeling, hybrid asynchronous additive and forming process design and modeling, experimental verification of ISM with simulated space conditions, post-process mechanical performance evaluation, prospective life cycle assessment, scenario analysis, and multi-objective decision-making, to pioneer the development of a sustainability framework for ISM. Sustainable ISM will also enable long-term space habitation and further exploration.