2025

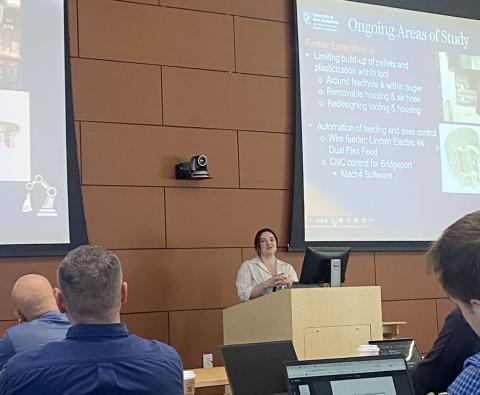

Last week, members of UNH's John Olson Advanced Manufacturing Center attended the 2nd Biennial Solid-State Additive Manufacturing—Technical Interchange Meeting (SSAM-TIM) in Waco, TX.

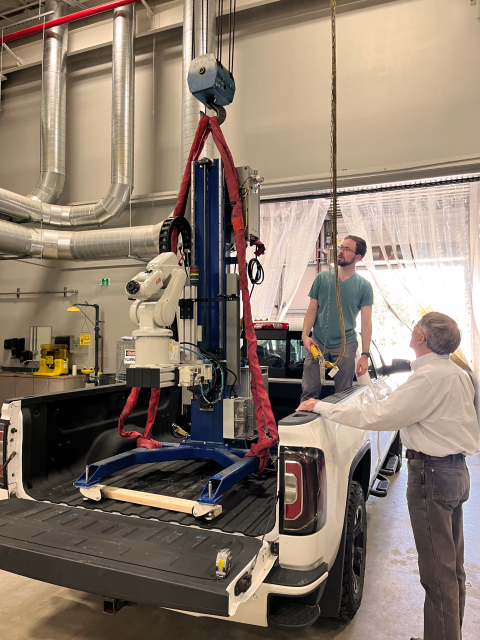

Cordi Norris presented on the Olson Center's friction stir additive manufacturing (FSAM) research. Her presentation, co-authored by graduate student Laura Catalano and Bucknell University's assistant professor Elizabeth Mamros, presented the center's work on building a portable industrial-sized robot to make high-quality parts for time-sensitive repairs to equipment in various isolated environments. The novelty of this robot is not only its portability but also its combination of CNC machining and additive manufacturing (think industrial 3D printing).

The UNH researchers and their partners at Bucknell University and Baylor University are designing a wire-fed auger system to continuously feed steel wire to the robot, which builds parts like a 3D printer. Moreover, the robot's CNC ability will convert scrap metal into thin wire, reducing waste and allowing for in-field part manufacturing.

Written by Katie Ahearn

The University of New Hampshire (UNH) welcomes Klein Marine Systems, a global leader in sonar technology, to the thriving network of business partners at the John Olson Advanced Manufacturing Center. On Wednesday, March 12th, Klein dedicated the "Klein Sonar Lab" and renewed its corporate partnership with UNH. To cement this relationship, Klein is lending an MX 600 Side Scan Sonar to UNH's Center for Coastal and Ocean Mapping/Joint Hydrographic Center (CCOM/JHC).

Klein Marine Systems, based in Salem, NH, is a world leader in Sonar Technology with over 60 years of experience; their sonar uses patented ALS (angle look sonar) and GAP filler technology to create a complete and continuous ocean floor map. A sonar's transducers illuminate the sea floor with pings of sound, which then reflect and return with images of the floor. Robert Glover, sales manager for Klein, explains it this way,

"Think about shining a light in a dark room and casting a shadow - You don't see the object – you see the shadow it makes." Glover calls this the art of sound, putting a sound wave in the water and watching it return, producing an image with ping after ping.

Traditional sonar is shaped like a torpedo, and its transducers (devices that convert electrical signals to sound) send out waves or pings of sound at an angle, creating a blind spot directly underneath. This blind spot is called the Nadir Gap. Klein's first-to-market ALS and Gap technology fills the Nadir Gap, creating a cohesive image in one pass. UNH students can use Klein's one-of-a-kind sonar to map NH's coastline and study animal habitats while learning about ALS and gap-fill technology. The sonar's presence at the University allows students and researchers to find new applications for this technology. Moreover, Klein's sonar products dominate the global market. Most students will never receive hands-on training like this, giving UNH's scholars a leg up well before graduating.

While CCOM/JHC will utilize the MX 600, the Klein Sonar Lab is located at UNH's John Olson Advanced Manufacturing Center on the west edge. How does aquatic sonar relate to an advanced manufacturing center? Glover explains, "We are really an engineering company. So, we work with clients to deliver a solution that is tailor-made for their specifications." Each customer or client has a different peripheral requirement depending on their use of sonar. Many of Klein's products are bespoke, particularly their products for various global militaries.

The Olson Center's experience with research, development, and prototyping and its grants with the Department of Defense makes it an ideal location for Klein to develop its products. Klein's Vice President and General Manager, Ted Curley, says,

"We are confident that the next generation of Klein sonar technology will be developed at our new Sonar Innovation Lab at the John Olson Center."

The Olson Center's first project with Klein was using an MTS (material tensile testing) machine to strength test Klein's break-away wing. This wing allows a sonar being pulled through the water to break away from the vessel if caught on the ocean floor and later retrieved with minimal damage. The strength test ensured the wing would disengage with the right amount of force, not before or after.

Recently, process engineer Nathan Daigle, with students Connor Bernard, Matthew McCoy, and Ana Ekstrom, built a to-scale 9' model of Klein's 5900 side scan sonar for trade show events. It is the Center's largest model to date, requiring a large-scale Modix 3D printer, 300 hours of printing time, and 20,000 grams of filament versus the average 300 grams it takes for most of the Center's prints. Bernard says of the experience, "It was a fun project because I got to use a larger scale additive printer, improving my skillset." John Roth, Director of the Olson Center, adds,

"These significant projects offer interns valuable experiences and demonstrate the real-world applications of their coursework."

Klein's relationship with UNH is not new, but the dedication of the sonar lab revives their presence on campus. Glover champions this relationship: "We're looking forward to getting back to hands-on learning with the students." The excitement is mutual for UNH; Marian McCord, UNH's Vice Provost for Research, says,

"This collaboration is all about driving discovery and innovation in a space where ideas can really take off. We're excited to get to work."

Written by Katie Ahearn

UNH student Charles Jones is taking innovation to new heights—literally! Watch as he showcases his drone skills, pushing the boundaries of tech and creativity. Big things are happening when Madco3D and The Olson Center join forces!

2024

Fall in New Hampshire is always an exciting time of year. As students return to classes and the leaves change, UNH's Space Tech Hub has ramped up its industry outreach. Over the past few weeks, Space Tech Hub Director Reka Winslow and her team have brought together UNH faculty and staff to meet with two aerospace and defense industry titans.

On October 22nd, BAE Space and Mission Systems (formerly Ball Aerospace) representatives visited the Durham Campus, including stops at the Space Tech Hub/Space Science Center, IOL, and Olson Center. Although a newly formed division of BAE Systems, Inc., through Ball Aerospace, BAE's new program has roots going back to the first days of the US space program.

On October 29th, Teledyne Technologies, a manufacturer of enabling technologies designed to sense, transmit, and analyze information for a wide range of industries, also visited these same facilities at UNH. As a leader in instrumentation, digital imaging, aerospace and defense electronics, and engineered systems, Teledyne can make advanced technology designs and measurement tools for any industry.

When visiting The Space Tech Hub at Morse Hall, visitors are shown the NASA flight-certified Thermal Vacuum Chamber, Flight Assembly, and Integration facilities with ISO 7 clean rooms, the Electronics Assembly Lab, and lastly, hands down, everyone's favorite room, the machine shop, where a combined 50+ years of experience machining space hardware and calibrating inspection equipment demonstrates the Space Science Center's strong history of participation in the US space program.

Companies like BAE and Teledyne have been working with space programs for decades, and partnerships with universities like UNH are key to the workforce pipeline as well as research and development. These relationships are symbiotic and establish networking systems.

Although recent visits to the Space Tech Hub have been from large corporations, the conversations are always clear: there is room at the table for everyone. It may seem daunting for a small business to join the R&D at UNH, but partnerships are available, and there are pathways. UNH has built a system for small businesses to access support, funding, and licensing. One place to start is UNH's webpage for businesses: https://lnkd.in/gCFEysd9. As the Space Tech Hub moves from fall to winter, it will focus on building the momentum these new relationships have ignited.

Written By Katie Ahearn

On Thursday, October 10th, The UNH Space Tech Hub welcomed the United Kingdom's Space Hub Yorkshire at Morse Hall. Representatives from both sides discussed the similarities between space technology initiatives in the UK and NH. Surprisingly, both regions face the same opportunities and challenges, albeit separated by an entire Ocean.

As an R1 Carnegie-classified institution, UNH is among the top 4% of research universities nationally and one of the nation's only 16 land, sea, and space grant universities. Two of Space Tech Hub's main contributions at UNH include training researchers and research and development for existing space programs.

Space Hub Yorkshire is a regional space cluster funded by the UK's Space Agency (UKSA). It focuses on building pathways for Yorkshire to enter the burgeoning global space economy. One of its primary goals is aiding businesses in becoming part of the downstream economy of space, i.e., healthcare, transportation and logistics, education and remote learning, and more.

Similarly to Space Hub Yorkshire, UNH has the unique ability to nurture the merger of regional businesses into the downstream economy of space. How does this work? Consider all the support space stations will require as the commercialization of space expands. While many new technologies are aimed at space, many can be implemented here on Earth. Growing space technology will also require local resources, supply chains, and the knowledge of many non-space-focused trades.

From transforming old coal mines in England into laboratories simulating extreme environments to the Space Tech Hub’s NASA-certified Thermal Vacuum Chamber, a wholly controlled space environment for testing, these institutions have their eyes on the stars. Discussions on Thursday included how the groups can work together.

Space Hub Yorkshire has found so much success in its coalition that it created Space North, a consortium of the UK's three northern space clusters. And as Space North says:

We are ambitious.

We are welcoming.

We look forward to working with you.

Written by Katie Ahearn

Watch PhD student Ola Ghattas and master’s student Marzan Alam discuss their work on Robots for Aging. This project, part of UNH’s Cognitive Assistive Robotics Lab (CARL), aims to improve the quality of life for patients with cognitive and physical disabilities by developing advanced robotic technologies designed to support them in their homes. Utilizing robotics and artificial intelligence, the project seeks to create tools that enable patients to maintain their independence and manage daily activities with ease.

On July 25th, the Olson Center welcomed the Northern New England chapter for Women in Manufacturing (WiM NNE) for a visit and round table discussion with Olson Center students. Students met with members of WiM and asked questions about their career paths in engineering as well as feedback and advice for their own educational paths and career goals.

The Women in Manufacturing Association is dedicated to supporting women in the manufacturing industry by providing impactful resources such as virtual learning, career fairs, and networking opportunities. With 33 U.S. chapters as well as international representation, more than 28,000 members have joined the association. WiM's Northern New England chapter oversees members from the states of Vermont, New Hampshire, and Maine.

WiM NNE is hosting a virtual event "Girls at Work, Inc. is Empowering the Next Generation" on Wednesday, August 21st from 9:30 AM to 10:30 AM. Join to learn how Girls at Work Inc., an organization from Manchester, NH, is building leaders and empowering young girls with power tools. Attendance is free for both members and non-members. Register here.

The Olson Center hosted two successful open houses during the Spring 2024 semester exposing students and families to the range of possibilities offered at the center. Thank you to everyone who could come and we hope to see you later this year at our Fall open houses!

2023

With nearly $3 million in NSF funding, researchers at UNH aim to create “In-Space Factories” that will utilize space resources for hardware fabrication. These researchers will address the growing problem that jeopardizes future expeditions by repurposing space debris. The Olson Center is proud to have Dr. John Roth and Dr. Brad Kinsey on the project team. We’re equally excited to host some of the project work at the Olson Center to contribute to this groundbreaking research and development.

read in-depth on this NSF grant and the research it will invoke

Visit the project page here:

Written by Katelyn Clark, '24

Roy VanGemert, from NHMEP, recently visited the Olson Center to test out his Machine operator training program that will strive to engage high schoolers in real-world manufacturing processes. It will also be provided to manufacturers training new employees or helping to retain existing staff. NHMEP has a strong partnership with the Olson Center, as they share resources and knowledge to help NH’s manufacturing industry.

Operating under the Department of Commerce and NIST (National Institute of Standards and Technology); NHMEP teaches all manufacturing disciplines using “Lean Principles” which is meant to improve a manufacturers efficiency. Additionally, they teach leadership, value stream, and even cybersecurity.

Roy’s training for high school students and community members will create a pipeline from the classroom to manufacturing companies. The goal is direct employment after the program is completed thus meeting NH’s workforce needs. Roy’s training course opens new pathways to students, showing that college or trade schools are not the only options for success.

Roy and NHMEP’s involvement with education and the Olson Center show great new beginnings in the future of manufacturing, and the paths that students can take to achieve their goals.

Written by Katelyn Clark, '24

Over the past academic year, the Oyster River High School robotics team has been working out of the Olson Center in preparation for the New England FIRST (For Inspiration and Recognition of Science and Technology) Robotics District Championship. This March; Oyster River’s team called Team Overdrive competed against 40 other teams across New England. In the seven weeks leading up to the competition, Saketh Kantipudi (ORHS junior and team captain) along with his 33 other teammates spent 30-40 hours each week using the Olson Center’s machinery, technology, and faculty/staff expertise.

The competition was held March 24th-26th at the University of New Hampshire’s Whittemore Center Arena. This is the team’s second year competing; however, they have grown immensely. Team Overdrive was split into sub-teams of mechanical engineering, electrical engineering, computer programming, business, and strategy. The Excellence in Engineering Award was given to Team Overdrive because of their high-level design and use of real-world engineering practices.

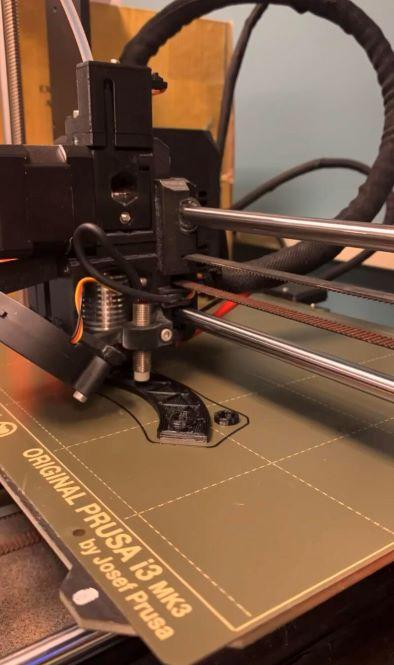

In the weeks leading up to the competition, Saketh and his teammates were able to use the center’s machinery and staff expertise to create and design their robot. Instead of buying parts, the team created every part of the robot at the center. Towards the end of the build season, the robot’s end effector broke, but the center’s 3D printer helped them create a new one in just days. Saketh explained that “The Olson Center allowed us to set higher goals and standards. We were introduced to higher-level engineering. Not just using the tools, but the idea of careers, real-world practice, and other centers like the Olson Center.”

The center allowed the team to have the freedom to work creatively and collaboratively as well as take the creation of their robot more seriously. Saketh and his teammates learned how to use the Prussia 3D printer, CAD software, the 3-axis CNC mill, the waterjet cutter, and the sandblaster to paint the robot.

The team is now in their off-season and is beginning to prepare for next year’s competition. Saketh says, “The team hopes to expand their knowledge and learn even more about new machines available to use at the Olson Center in the upcoming year.”

Written by Jesse Davis

In August of 2022, The Olson Center’s mini ABB Robot was sent to Vermont in partnership with Massive Dimension and ABB. Located in Barre, Vermont, Massive Dimension specializes in additive manufacturing. The company sells raw materials, extruders, components, accessories, and printing cells for robotic 3D printers.

The goal of the partnership was to enable the printing technology developed by Massive Dimension to be adapted for deployment on ABB robotic systems. Using robotic arms for 3D printing expands a facility’s manufacturing capabilities because of the arms’ unique range and mobility. A robot arm allows for a larger range of motion and increased printing size, as well as allowing non-planar (multi-axis) printing. Traditional gantry-based 3D printing methods are limited to flat layers of plastic. A robot arm can print objects from different angles, including the side of a part and, potentially, underneath. Companies like Massive Dimension are also working on expanding the types of materials that can be used in 3D printing, such as concrete and metals.

The Olson Center Director, John Roth, and Program Manager, Nathan Daigle, were happy to support a growing collaboration with MD and ABB as they work together to develop and refine printing technology. The center’s faculty and staff look forward to working with Massive Dimension in the future.

Written by Katie Ahearn

Interesting fact about the Olson Center robot: The mini-ABB mobile robot station was built by students at the Olson Center to augment the robot with an integrated 7th-axis of motion which allow for programs to be developed that increase the distance of the base of the robot from the ground. Leveraging this additional axis allows for the height of the 3D print to be dramatically increased. - John Roth

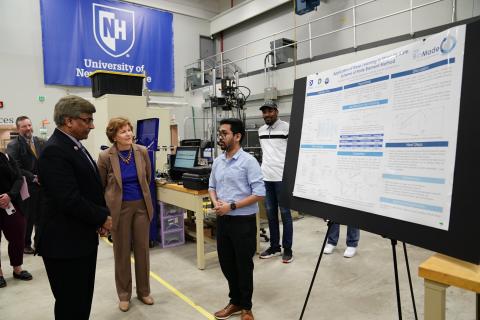

On Friday, May 12, 2023, Senator Jeanne Shaheen (D-NH) and the National Science Foundation’s (NSF) Director Sethuraman Panchanathan visited UNH’s John Olson Advanced Manufacturing Center as part of a larger visit to the Durham campus. As an R1 research institute, a large portion of the university’s research is done through NSF grants.

As a part of the tour, the Senator and the Director met with Jim Brown and Michael Gleason from GreenSource, a New Hampshire based manufacturer of high-quality printed circuit boards and one of the Olson Center’s key strategic partners. Drop-Slice, a non-abrasive, vacuum based waterjet start-up spun out of the Olson Center, also contributed to the tour. Collaborative projects with Madco3D (energy-efficient housing and the printing of coral reefs) were also discussed with the Senator and the Director.

Brad Kinsey, the Associate Dean of the College of Engineering and Physical Science, spoke about NH BioMade, which researches the design and manufacturing of biomaterials. This program also supports NH’s biomaterials industry through partnerships and workforce development. Much of the UNH research for NH BioMade was done at the Olson Center.

Diane Foster, Director for the School of Marine Sciences and Ocean Engineering, and professors Ruth Varner, Julie Bryce, and Jessica Ernakovich, along with several other team members, also presented on UNH’s Arctic Research and CARPE (Convergent Arctic Research Perspectives and Education). Supported by NSF, CAPRE prepares graduate students for academic and non-academic careers that address challenges caused by the Arctics changing climate.

Before the visit continued to other UNH centers, several graduate students from NH BioMade and CARPE were able to discuss their research with Director Panchanathan and Senator Shaheen. The visit highlighted UNH and the Olson Center’s far-reaching impact on NH’s economy through NSF’s investment in programs like NH BioMade and CARPE.

Written by Katie Ahearn

Helping to bridge the skills and technology gap in the nation’s $2.3 trillion manufacturing industry, the Olson Center assists local, regional, national, and international companies with navigating the continually evolving advanced manufacturing landscape; helping them remain competitive in today’s global environment. The Olson Center serves as the hub through which manufacturers can: develop connections up and down the supply chain; seek assistance solving today’s complex product, materials, and manufacturing problems; engage with world-renowned researchers and engineers; fulfill workforce and educational development needs; and examine/deploy the latest technologies, processes, automation, and manufacturing techniques.

On Thursday May 25, 2023 Dr. Peter Abbott OBE, British Consul General to New England and his team visited the UNH Durham campus as part of a week-long trip to the state. The regional office located in Boston MA serves as a liaison for British and U.S./New England relationships regarding politics, the economy, industry, and security.

The day began at The John Olson Advanced Manufacturing Center’s where the center’s director John Roth and UNH’s senior leadership; Provost Wayne Jones, Vice Provost Marian McCord, Dean Cyndee Gruden and public affairs manager Thomas Cronin welcomed Dr. Abbott. After introductions, the team was lead on a tour of the manufacturing high bay. Discussions included UNH’s unique relationship with industry partners and how the universities’ approach differs from other academic institutions across the country.

In addition to touring the manufacturing space, the tour included presentations by Associate Dean Brad Kinsey, and Ph.D. student, Shayan Darzi. Both spoke about their work for NSF EPSCoR’ s NH BioMade. The project combines research at universities and colleges across the state with workforce development initiatives.

The remainder of the day included tours of: Chase Ocean Engineering Lab, Space Science Center, UNH-Innovation and InterOperability Lab, The University Instrumentation Center, Woodman Farm and the UNH Brew Lab. Each center is a UNH showpiece due to their staff’s unique research capabilities. From chemistry, engineering, ocean science, agriculture, and space; they offer varying types of networks and collaborations as well as expertise in their fields. The day highlighted the potential to partner with industry and foster relationships between the U.K. and New England.

Written by Katie Ahearn

Helping to bridge the skills and technology gap in the nation’s $2.3 trillion manufacturing industry, the Olson Center assists local, regional, national, and international companies with navigating the continually evolving advanced manufacturing landscape; helping them remain competitive in today’s global environment. The Olson Center serves as the hub through which manufacturers can: develop connections up and down the supply chain; seek assistance solving today’s complex product, materials, and manufacturing problems; engage with world-renowned researchers and engineers; fulfill workforce and educational development needs; and examine/deploy the latest technologies, processes, automation, and manufacturing techniques.

Taylor Caswell, the commissioner of the New Hampshire Department of Business and Economic Affairs (BEA), visited the John Olson Center Wednesday April 26, 2023. Also attending were business development manager Mark Laliberte, director of intergovernmental affairs Alex Fries, and deputy director Cynthia Harrington.

Commissioner Caswell learned more about how the BEA can partner with the Olson Center to help New Hampshire-based manufacturers thrive. The visitors discussed how the BEA can help New Hampshire based companies grow from startups all the way up to large organizations. The conference portion of the visit looked into how UNH can best work with the state in order to further the advanced manufacturing growth on and off campus.

Several of our key New Hampshire-based business partners — Exhail, GreenSource, Airtho, Madco3D and DropSlice — discussed projects where they have partnered successfully with the Olson Center. Additionally, an informative tour of the factory floor allowed the BEA team to view projects in process.

The BEA works to enable and grow the vitality of the N.H. economy for residents and employers of New Hampshire. They strive to enhance sectors of New Hampshire including healthcare, tourism, life sciences, construction, and advanced manufacturing, leading them to visit the Olson Center.

Written by Lauren Dupuis, '25

The Olson Center welcomed U.S. Senator Maggie Hassan February 13th, 2023. During the hour-long visit, Senator Hassan toured the Olson Center factory floor and talked with representatives from UNH, and several New Hampshire-based manufacturing companies about workforce needs, methods for increasing industry-university collaborations, and other pertinent topics. The tour demonstrated some of the many ways that industry leverages the Olson Center’s facilities and capabilities. Companies in attendance included Airtho, Drop-Slice, Exail, Greensource Fabrication, and Madco3D, each of which is currently partnering, or looking to partner, with the center.

During the roundtable portion of the visit, the Senator sought suggestions to create more traditional and non-traditional education and workforce pathways. She shared information on various opportunities that are being created within the federal government that are designed to ease workforce shortages. The Senator also listened to the concerns and challenges that are being faced by N.H. manufacturers and provided insight into ongoing efforts to stabilize U.S. supply chains.

Written by Lauren Dupuis, '25

2022

The Olson Center was recently given the opportunity to design and build a set of respirometry chambers and multiple stir bar plates for the lab of Dr. Brittany Jellison, a marine scientist at the University of New Hampshire’s College of Life Sciences and Agriculture department. Dr. Jellison, along with graduate students, will be using the respirometry chamber for their research.

The respirometry chambers will be used to study the respiration of sea snails and other small sea animals. The chambers are sealed containers of water where the sea snails will be placed, with a guard protecting the snails from the magnetic stir bar. The chambers and stir bar platform are fully submersible and sit in a cold-water bath to maintain a constant temperature.

Olson Center interns that were a part of this project include David Pekkala, Jackson Penney, Yeonji Ha, and intern director, Nathan Daigle. The center’s 3D printer and waterjet cutter were used extensively in the fabrication of the respirometry chamber system. We are excited to continue working with the University of New Hampshire and to be a part of new and exciting research endeavors

UNH College of Life Sciences and Agriculture

#engineering #marinescientist #olsoncenter #UNH

Written by, Jesse Davis

UAV Hover Board

Last month, Professor Nathan Laxague and his group, Coupled Air-Sea Surface Layers Laboratory tested the control and navigational ability of their UAV hoverboard at the Olson Center. The UAV was from Freefly Systems designed to carry large and heavy payloads. As part of their group’s research, the UAV will soon be flown over the ocean to measure waves and surface currents.

Written by, Jesse Davis, class of 2025

Olson Center intern, Gracie Schmidt has been working with Northeast Passage to create a recumbent bike pedal (using Olson Center 3D printer) for stroke victims that might have limited mobility/flexibility in one side of their body. Gracie has created this pedal for a setting where an individual can just strap on the pedal to an already existing one.

By, Jesse Davis

Gracie's Bike Pedal

Bike Pedal

Fender prototype on the double sided incremental forming (DSIF) machine