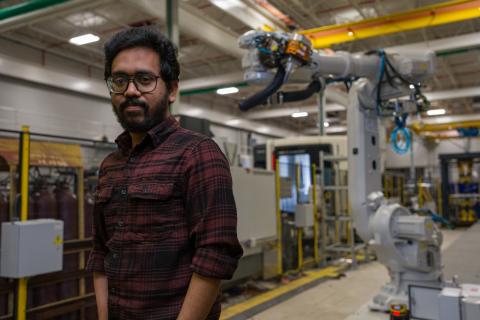

The Olson Center provides students with the resources and space to immerse themselves in their research and new findings. Graduate student, Abrar Ebrahim has done just that as he is currently pursuing his Ph.D. in metal forming and plasticity after obtaining his master's degree in metallurgical and materials engineering from the Indian Institute of Madras, Chennai, India. Abrar’s current research (funded by NH BioMade) focuses on integrating machine-learning techniques into the fields of metal-forming and plasticity. More specifically, he has devised machine-learning models capable of accurately capturing the anisotropy and strain-hardening characteristics of commercially pure titanium. These models have been successfully applied to predict plastic deformation at different temperatures and strain rates within finite element analysis (FEA) simulations.

Throughout Abrar’s research, he has used various Olson Center machinery, including the abrasive water jet, 3-axis CNC machine and 3D printers for sample preparation, as well as the MTS Universal testing machine and cruciform machine for material characterization.

Abrar is halfway through his Ph.D. research and looking forward to continuing his work with titanium. He explained that the end goal of his work is to locally alter the mechanical properties of pure titanium and form medical implants using incremental forming.

While Abrar’s research at the Olson Center has been a prominent part of his time in New Hampshire, he also explained how he has enjoyed the different lifestyle, culture, cuisine, and landscape New Hampshire has to offer. One of Abrar’s favorite hobbies has been hiking and exploring the state’s many waterfalls.

Written by Jesse Davis, Class of 2025

Photo by UNH Photographer Jeremy Gasowski