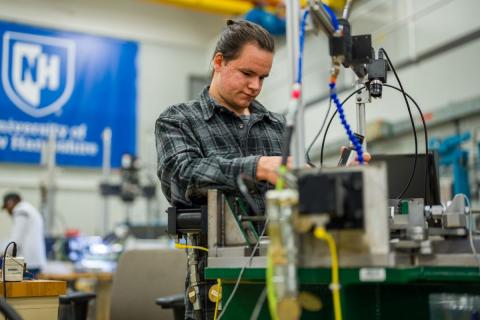

The Olson Center's innovative technology and machinery create a space where students can immerse themselves in research opportunities and take their findings to new heights, as UNH student Matt Eaton did for his senior capstone project.

Matt spent time at the Olson Center under the mentorship of Professor Jinjin Ha, who provided him with expertise and insight into his designs and research. Matt's use of the Center's materials and technology enabled him to conduct a concise and in-depth exploration of the Development of In-Plane Torsion Testing Fixture and Experiment for Sheet Metal which he presented at UNH's Undergraduate Research Conference. He was awarded first place in the mechanical engineering research category.

Matt worked on designing a fixture and specimen for measuring shear deformation in sheet metal discs loaded in torsion. He used the Olson Center's 3D printer to print test parts and the waterjet machine to cut specimens. Matt performed finite element studies on various specimen geometries to determine a specimen and clamping mechanism that would work best for a wide range of materials to be tested. Once his design was finalized, he analyzed the results of the finite element studies to determine how different methods of calculating shear strain would deviate from the expected material properties.

The fixture Matt designed is almost complete. He will begin the physical testing using Professor Ha's MTS machine at the Olson Center this summer.

The Center would like to congratulate Matt Eaton for his hard work and dedication to his research.

Written by Jesse Davis

Photo by Jeremy Gasowski