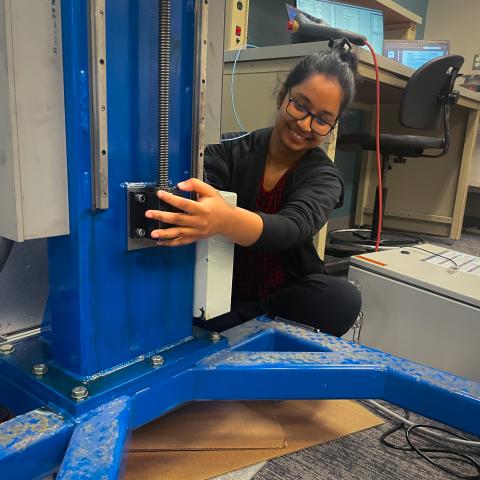

Meet Rokeya Sarah, an Olson Center student intern and a rising junior at Keene State College (KSC) majoring in Sustainable Product Design and Innovation (SPDI). Rokeya's interest in engineering began in 6th grade while watching her brother study to be an architect. Seeing his designs inspired her curiosity about technological innovation. Over time, her interest developed, leading her to pursue a career in engineering aimed at advancing modern technologies.

Rokeya's undergraduate studies at Keene's SPDI program brought her to the attention of KSC Professor Lisa Hix, who is sponsoring her internship at UNH's Olson Center through an NSF/NH BioMade seed grant. This summer, Rokeya joined project manager Nathan Daigle in converting the Olson Center's (mini) ABB IRB 120 robot into a portable mobile robot station with 3D printing abilities. The inspiration for this project is the mobility perspective, which considers the possibilities of 3D printing on-site versus printing and transporting.

Daigle's undertaking started with expanding the robot's printing capacity by adding a 7th axis through an in-house-built elevator stand, allowing it to move vertically. When asked to expand on the concept of axes in robotics, he states,

"A robot's axes describe how it can move. Some say "degrees of freedom (DoF)" rather than axes. You need at least 6 DoF to freely position and orient in 3D space. Adding a 7th or even 8th axis can extend the robot's range of motion."

The mobile station is further equipped with a Massive Dimensions 3D print head and a programmable logic controller (PLC) that sends signals to the motor controlling the mini ABB, print head, and elevator. Rokeya's part in the project is programming the ABB's robot arm to send signals to the PLC and configuring the controller to send signals to the motor. The challenge is writing detailed code that coordinates the robot, print head, and elevator to move with smooth and precise movements for a flawless print. The final product will have a human-size printing range, roughly 5ft by 3ft.

Additionally, the project requires a virtual simulation (sim) of the robot to mimic the printing process before each print. Using Robot Studio, ABB's software package, Rokeya is designing the sim to review and map every planned print to ensure the robot does not physically crash while printing. Moreover, Daigle states that the simulation will help teach students at the Olson Center about

"Robotics integration, automated product process development, and common considerations in the 3D printing process."

When asked how this internship has shaped her career path, Rokeya expressed that while design and manufacturing have always been her focus, she expanded on her course work at KSC in mechatronics and this summer has opened her eyes to the wider world of robotics and automation, which she now wishes to pursue. With her sights set on graduate school, the skills she has acquired over the past six weeks are another significant step towards her academic and professional aspirations.

"Coming here was like a dream come true for me, and working in a professional environment like this, everything has been new."

Rokeya's time at the Center is a testament to the growing relationship between KSC and UNH. These types of partnerships across the state are instrumental in building the economic and educational strength and workforce development New Hampshire can offer its residents. Expanding students' access to the various facilities in the university system opens the door to success across the region.

Written by Jane Matthews and Katie Ahearn