Mechanical Testing

- Tensile and Compression from 100 Newtons to 250 KiloNewtons

- Infrared Temperature Imaging

- High Speed Digital Image Correlation

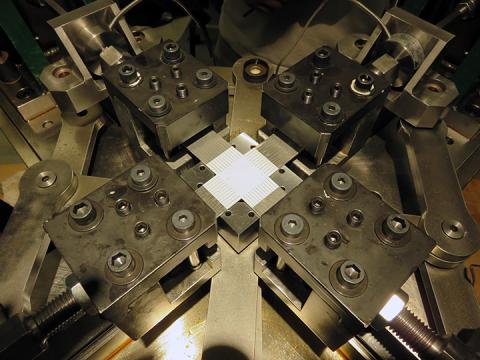

- Biaxial Tensile Testing for Sheets

- Hardness (standard, micro, and nano)

- Cyclic Fatigue Testers to 10,000 cycles/hr., at 1800°F

- Multicomponent Dynamometer

For more information on mechanical testing visit the Mechanics, Materials, and Manufacturing Lab.

Materials Characterization

- X-Ray Diffraction

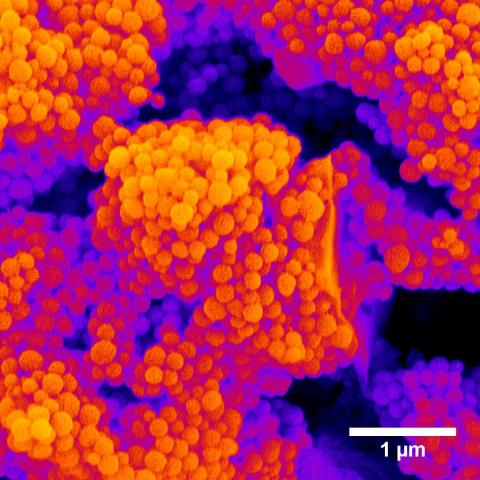

- Scanning Electron Microscopy

- Transmission Electron Microscopy

- Atomic Force Microscopy

- Confocal Microscopy

- Triboscope Nano Indentation System

- Nuclear Magnetic Resonance (NMR)

- Spectrophotometers ( UV, VIS, FTIR)

- Viscometers

- Gas Chromatographs (GPC)

- Differential Scanning Calorimetry (DSC)

- Thermogravimetric Analysis (TGA)

- Dynamic Mechanical Analysis (DMA)

- High Performance Liquid Chromatography (HPLC)

For more information on materials characterization visit the University Instrumentation Center.

Manufacturing Processes and Synthesis

- Pulsed Laser Deposition System

- Solar Photo Catalysis Lab

- Electromagnetic Welding

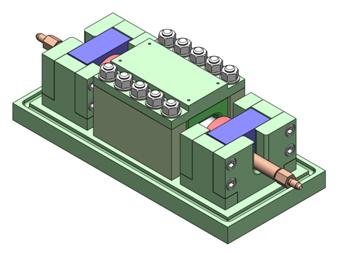

- Tube and Sheet Hydroforming

- 50 Ton Servo Hydraulic Forming Press

- Additive Manufacturing

- Object Multi-material 3D Printers

For more information on Manufacturing Processes visit the Mechanics, Materials, and Manufacturing Lab.

Modeling Software

- FEA: Abaqus, MSC.Marc, MSC.Dytran, Aqua-FE, Deform

- Mastercam, Dream.3D, Solidworks